It’s been a couple of weeks since the last update and with about 5 weeks to go before the shipping date it’s been a week of checking and re-checking what needs doing still and that we are still on track both in time and budget. Fortunately, so far, it’s looking pretty good, let’s hope it stays that way 🙂

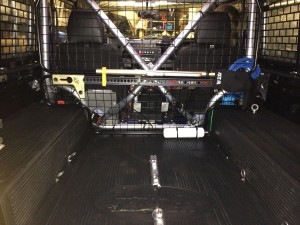

The Hi-Lift mount is done, painted and fitted, I got some M10 ring nuts as an impulse buy while perusing an online nut and bolt shop (as you do) and it turns out they are perfect as a way of securing the Hi-Lift to the mount and providing extra tie down points. With the design I eventually came up with the Jack is secured with a single one of these nuts and is held securely with no rattling. A second nut can be added to the foot for additional security but isn’t really needed.

The Hi-Lift mount is done, painted and fitted, I got some M10 ring nuts as an impulse buy while perusing an online nut and bolt shop (as you do) and it turns out they are perfect as a way of securing the Hi-Lift to the mount and providing extra tie down points. With the design I eventually came up with the Jack is secured with a single one of these nuts and is held securely with no rattling. A second nut can be added to the foot for additional security but isn’t really needed.

Another in the long list of jobs I’ve been meaning to get around to was to make a cover for the ECU, or at least a cover for the wiring going into the ECU. Being behind the seat we’ll probably end up stuffing clothes, water, snacks and who knows what else behind the seats and there was always a danger that this would stress a wire or separate a plug so it needed to be a bit more robust.

Another in the long list of jobs I’ve been meaning to get around to was to make a cover for the ECU, or at least a cover for the wiring going into the ECU. Being behind the seat we’ll probably end up stuffing clothes, water, snacks and who knows what else behind the seats and there was always a danger that this would stress a wire or separate a plug so it needed to be a bit more robust.

in between rain showers and F1 coverage I ended up making 3 different covers, the first out of cardboard to use as a template, the second out of aluminium based on the template and the third because the first two didn’t quite fit right ! Third time lucky though and I’m quite pleased with the result, not too intrusive and covers all the important bits while allowing access to the fuse box and relays.

One other thing we’ve “ticked off” this week is the MOT test, the MOT is/was due to expire in March 2014 which isn’t ideal so we’ve taken it for an MOT 5 months early so it will be fully UK road legal throughout the trip (one of the requirements for use in Australia as a foreign vehicle). As expected (although always a relief !) it passed without any problems/advisories.