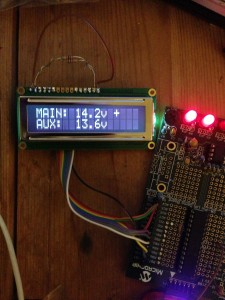

The dual battery system has been missing a couple of things since I first installed it and I’ve spent a few evenings this week playing with a PIC chip and an LCD display. The aim is to have some way of checking the charge level of both batteries and to control the automatic charging of the secondary battery when the main battery is at a reasonable voltage. It will always have the manual overrides of either permanently connecting the aux battery (to jump start the main) or having it disconnected if I want to put all the charge into the main.

The dual battery system has been missing a couple of things since I first installed it and I’ve spent a few evenings this week playing with a PIC chip and an LCD display. The aim is to have some way of checking the charge level of both batteries and to control the automatic charging of the secondary battery when the main battery is at a reasonable voltage. It will always have the manual overrides of either permanently connecting the aux battery (to jump start the main) or having it disconnected if I want to put all the charge into the main.

As the PIC chip I’ve chosen has plenty of spare capacity I also added provision for it to display the fuel level in each fuel tank too, alternating every 10 seconds between the fuel levels and the battery levels/voltage.

I’m currently using a 16×2 character display but the finished version will be 2×8 characters, allowing it to take up less dashboard space. The programming is just about done apart from calibrating the fuel levels against the two sender units, just need to build the design into something a bit smaller now !

The chip I’m using has another 4 spare analogue inputs so I might add some additional warning monitoring into it yet. Maybe gearbox temperature, fuel pressure perhaps, turbo boost pressure, I’m fitting a dedicated monitoring system so I’ll see what that’s missing and maybe add them into this chip/display. It’s always better to know when something’s starting to go wrong rather than a complete failure being the first sign of trouble.